Lower centre of gravity: Split Gooseneck structure allows the weight of the cargo to be lowered during transport. Thus, the detachable trailers are more stable. The risk of rollover is mush lower for detachable trailers. Dispersion Impact: The design is effective to disperse the impact force from the road. The likelihood of damage to vehicle and cargo is easy to be decreased. The safety of the whole traffic should not be worried.

1. Structural features of split gooseneck

1. Structure of split gooseneck

The split gooseneck is a unique low-profile design. The core of the design is to divide the one-piece gooseneck into two parts, top and bottom. Connecting and disassembling is realized by flexible connecting method. This design makes the cargo more stable and flexible. Particularly, the total centre of gravity is reduced.

2. Differences from traditional gooseneck

Traditional gooseneck structures are generally welded together. As a result, it is not flexible. It's hard to get used to various heights and loads. The split gooseneck owns a more flexible connection method. It allows easy adjustment of the angle and height of each component. Furthermore, each part of the divided structure owns its bearing system. M efficient sharing of load is allowed by detachable trailers. The overall efficiency of transport is enhanced.

2 Axle 60 Tons Detachable Trailers in Congo

2 Axle 60 Tons Detachable Trailers in Congo

2 Axle 60 Tons Detachable Trailers in Congo

2 Axle 60 Tons Detachable Trailers in Congo

2 Axle 60 Tons Detachable Trailers in Congo

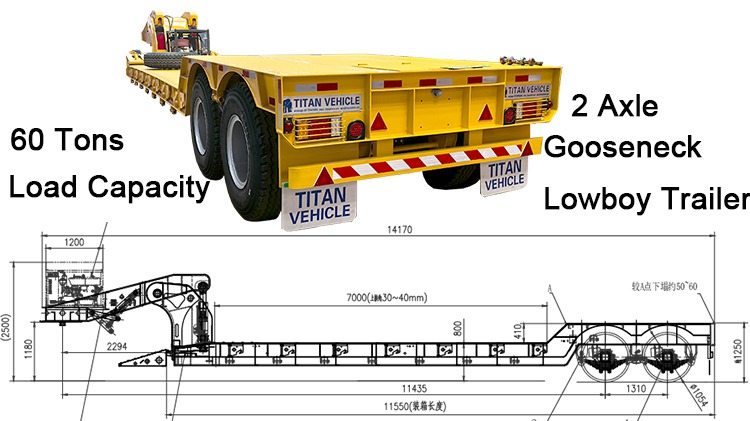

Dimension: 14170mmx2500+(250*2)mmx2500mm

Loading capacity(T): 60 ton

Axle: 2 axles, FUWA/BPW/TITAN Brand

Tire: 8units, 12R22.5

Suspension: Mechanical suspension

Spring leaf: 120(W)mmx16(Thickness)mmx10 layers

1. Strong adaptability

Adjustable Height: The split design allows for adjustment of the weight of the load. It's benificial to satisfy the requirements of ultra high loading and normal loading. Various facilities are easy to accommodate.

Versatile: It is applied to the transportation of heavy equipment or construction machinery. It's also popular to ship super heavy goods. The application range of detachable trailers is expended to satisfy various traffic demends.

2. Enhance carrying capacity

Weight distribution: Split design support even distribution of heavy loads. Deformation due to excessive local force is avoided. It contributes to better carrying capacity of the detachable trailers.

Reduce Deformation: Detachable trailers is specially designed to withstand heavy loads. The higher stability of the equipment in the transport process is achieved.

3. Easy to load and unload

Flexible Loading and Unloading: Detachable trailers own a transfer ramp. In combination with a hydraulic system, it makes it more convenient to load and unload. It's crucial to realize quick and safe loading and unloading.

Multi-Angle Loading and Unloading: The design is designed to support loading and unloading at various angles and heights. The entry and exit of large equipment is facilitated. The efficiency and security of work is enhanced.

4. Lower maintenance costs

Wear Resistance: Detachable trailers are less likely to wear under stress than traditional designs. This implies a reduction in the frequency of maintenance. There will be a reduction in the operational costs of the business.

Easy replacement and repair: The split structure is helpful to decrease the maintenance cost in the long term. When a part is damaged, it is easier to repair or replace it.

5. Split Goosenecks Application Scenarios

The detachable trailers is designed to be ideal for heavy traffic. It's clear to be seen in a wide range of industries.

Transport of heavy machinery: For instance, the transport of large equipment. Such as excavators, cranes.

Transport of construction materials: It is applicable to the transport of steel reinforcement and concrete parts.

Long distance transport: It is applicable to transport large equipment across the city. The detachable trailers is based for better security and comfort.